Applications

LIST OF COMMON DRY ICE BLASTING APPLICATIONS

MANUFACTURING APPLICATIONS:

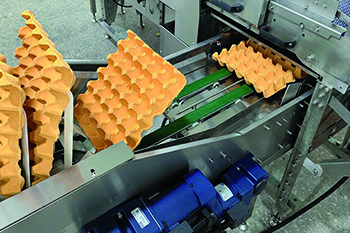

- Sanitary cleaning of food processing & production equipment

- Weld cell cleaning, including robots & other equipment

- Production equipment

- Automotive parts

- Core boxes, aluminum molds

- Paint booths

- Ventilation systems

- Foundries

- Meat processing plants

- Rubber & plastic molding machines

- Rubber curing equipment

- Removal of inks from commercial printing presses

- Bottling industry

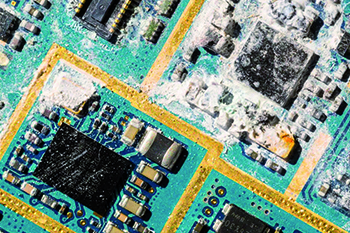

- Computer chip industry

- Pharmaceutical industry

- Packaging equipment

COMMERCIAL APPLICATIONS:

- Restaurants – grills, ovens & vents

- Residential cleaning – including homes, public parks, restrooms, etc.

- Mold remediation

- Fire restoration

- Historical restoration

- Wood finishing and restoration

- Automotive repair & service centers

- Graffiti removal for DOT, Government, Commercial (railcars, bridges, signs, buildings)

- Asphalt & concrete trucks

- Cemeteries and monuments

- Accident and crime scene clean-up

- Wine barrels

OTHER APPLICATIONS:

- Electrical and power generation equipment including transformers, sub-stations, wind turbines and generators

- Dry docking – commercial & military (ships & subs)

- Removal of algea, sea slime, salt buildup, etc. from boat hulls

- Commercial and military aircraft (engine, landing gear, etc.)